VCM/CPM

CLEAN WATER CENTRIFUGE PUMP

- Product description

- Model parameter table

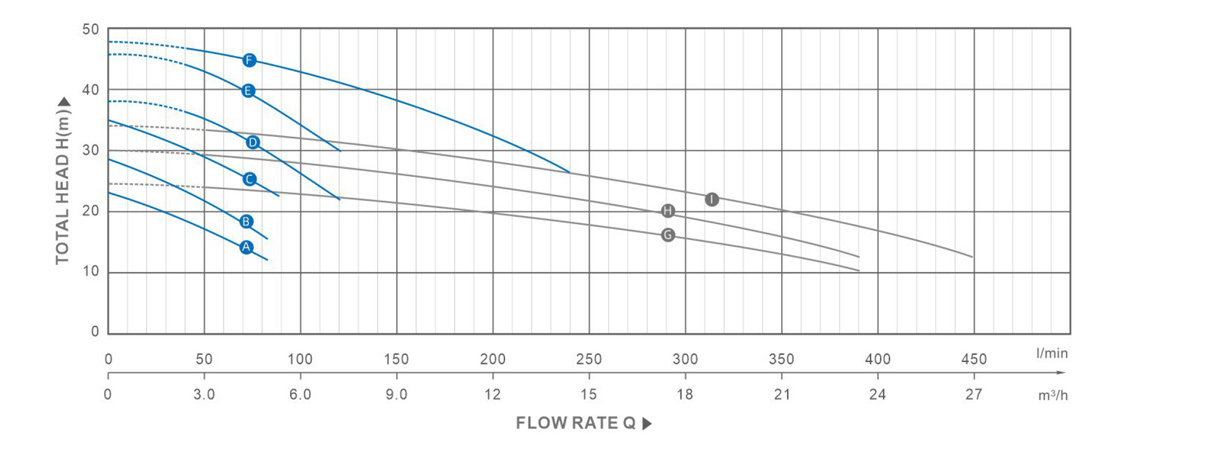

- Performance curve

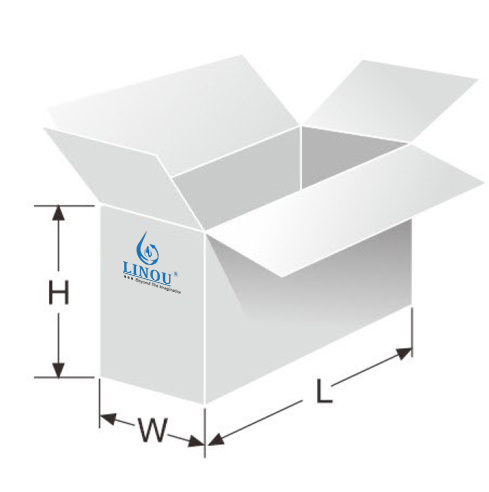

- Package

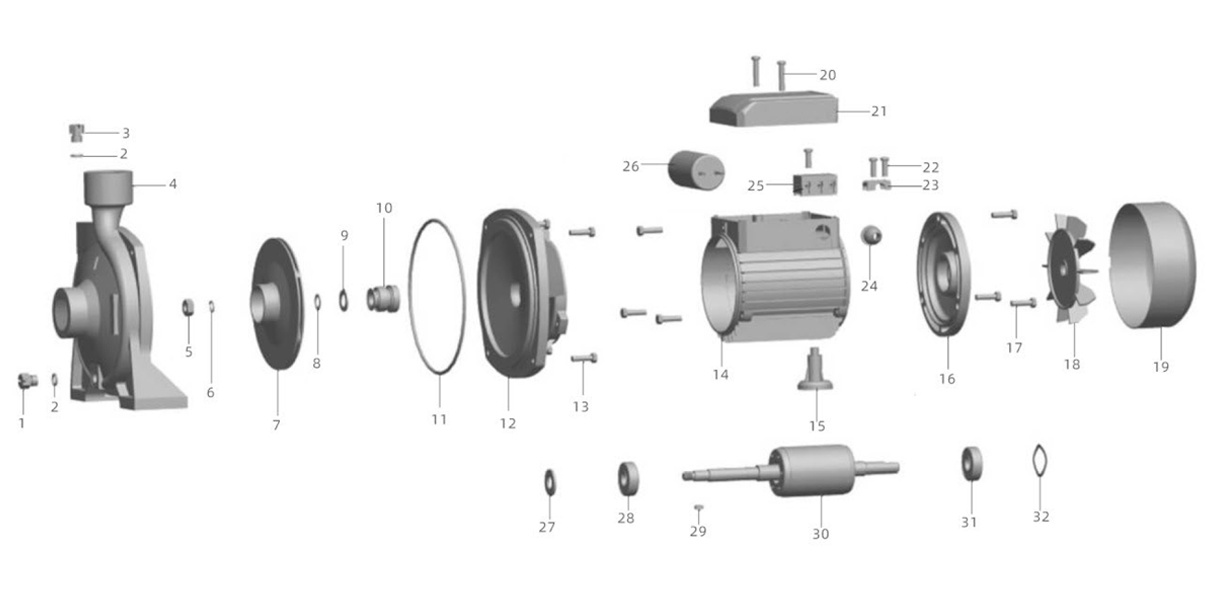

- Parts

-

Applications

● Suitable for use with clean water and liquids that are not chemically aggressive towards the materials from which the pump is made.

● As a result of their reliability and the fact that they are easy to use, these pumps are widely used in domestic and civil applications such as the distribution of water in combination with small and medium sized pressure sets, for transferring liquids and for the irrigation of gardens and allotments. The pump should be installed in an enclosed environment, or at least sheltered from inclement weather.Motor

● Two- pole induction motor(n=2850 r.p.m)

● Insulation Class B

● Protection IP44

● Continuous service S1

● Thermal protector for single phase

● Single-phase 220V/50Hz, 60Hz if request

● Three-phase 380V/50Hz, 60Hz if requestOperating conditions

● Liquid temperature up to 60°C

● Ambient temperature up to 40°C

● Total suction lift up to 8m

Component Construction

● Pump body: Cast iron

● Pump support: Cast iron

● Motor housing: Aluminum

● Impeller: Brass

● Motor shaft: Carbon steel, AISI304 SS if request

● Mechanical seal: Ceramic/ Gra phite (0.5HP), SIC/GraphiteKey words:- 3dcqg

- table

- tr

- table-responsive

- 36

- td

- 0.75

- background

- voltage

- solid

-

(50Hz n=2850 rpm/min)

Model

Inlet/ Outlet

Power

Flow

FlowQ(m3/h) 0 0.6 1.2 1.8 2.4 3.0 3.6 4.2 4.8 5.4 7.2 10.8 14.4 18 21.6 23.4 25.2 27 Inch kW HP (L/min) 0 10 20 30 40 50 60 70 80 90 120 180 240 300 360 390 420 450  VCM22 CPM130

VCM22 CPM1301"x1" 0.37 0.5 H(m)

23 22 21 20 19 18 17 16 14 - - - - - - - - -  VCM42 CPM146

VCM42 CPM1461"x1" 0.55 0.75 28 27 26 25 23.5 22 20 18 16 - - - - - - - - -  CM50 CPM158

CM50 CPM1581"x1" 0.75 1.0 36 34 33.5 33 32.5 31.5 30 29 27 25 - - - - - - - -  CPM170

CPM1701"x1" 1.1 1.5 - - - 38 37 36 35 33.5 32 30 22 - - - - - - -  CPM190

CPM1901"x1" 1.5 2.0 - - - 46 44.5 43 41.5 40 38 36 30 - - - - - - -  CPM200

CPM2001"x1" 2.2 3.0 - - - - - 46 44.5 43 41.5 40 34 30 26 - - - - -  VCM60

VCM601"x1" 1.1 1.5

25 - - - - - 24 23.5 23 22.5 22 21 18.5 16 12.5 10.5 - -  VCM70

VCM701"x1" 1.5 2.0 30 - - - - - 29 28.5 28 27.5 27 25.5 22.5 19 15 13 - -  VCM80

VCM802"x2" 2.2 3.0 34 - - - - - 33 32.5 32 31.5 30 29.5 27 23.5 20 17.5 15.5 13 -

n=2850 rpm/min

-

Model

Inlet/Outlet

N. W

LxWxH

Inch Kg mm

1"x1" 8.5 270x1 90x240

1"x1" 11.5 320x 200x255

1"x1" 13.5 320x215x270

1"x1" 20 380x265x325

1"x1" 21 380x265x325

1"x1" 22 380x265x325

2"x2" 22.5 420x245x305

2"x2" 23.5 420x245x305

2"x2" 28 440x245x305 -

Materials Table

NO. Part Material 1 Discharge plug Brass 2 "O"ring Rubber 3 Charge plug Brass 4 Pump casing Iron 5 Nut STEEL 6 Spring gasket STEEL 7 Impeller Brass/PPO 8 Snap ring STEEL 9 Washer STEEL 10 Mechanical seal Ceramic graphite 11 "O"ring Rubber 12 Pump support Iron 13 Bolt STEEL 14 Casing with wound stator Cast aluminum 15 Stand ABS 16 Driving cap Iron 17 Bolt STEEL 18 Fan POM 19 Fan cover STEEL 20 Bolt STEEL 21 Terminal cover ABS 22 Screw STEEL 23 Cable presser ABS 24 Fairlead Rubber 25 Terminal board Assembly 26 Capacitor Assembly 27 Drops guard Rubber 28 Bearing Assembly 29 Key STEEL 30 Rotor Assembly 31 Bearing Assembly 32 Split ring STEEL

Related products